Although TFT LCDs are the industry standard for most OEM applications,they are susceptible to damage in harsh/rugged environments. The outer layer of an LCD is easily scratched and the glass TFT layer susceptible to cracking from impact or excessive vibration.

Although TFT LCDs are the industry standard for most OEM applications,they are susceptible to damage in harsh/rugged environments. The outer layer of an LCD is easily scratched and the glass TFT layer susceptible to cracking from impact or excessive vibration.

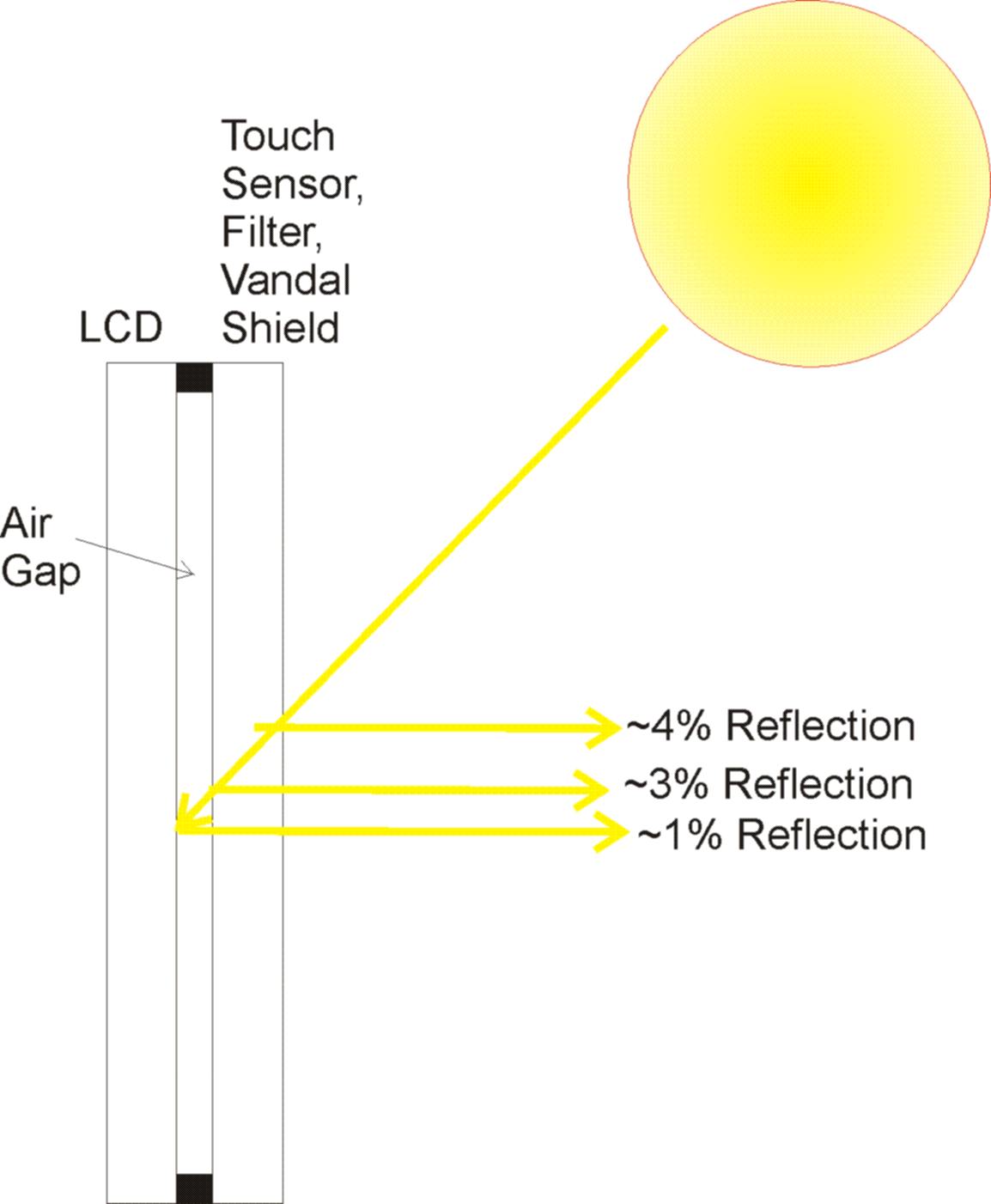

Additionally, a standard TFT LCD does not have the brightness and contrast characteristics that enable outdoor or high ambient light viewability.

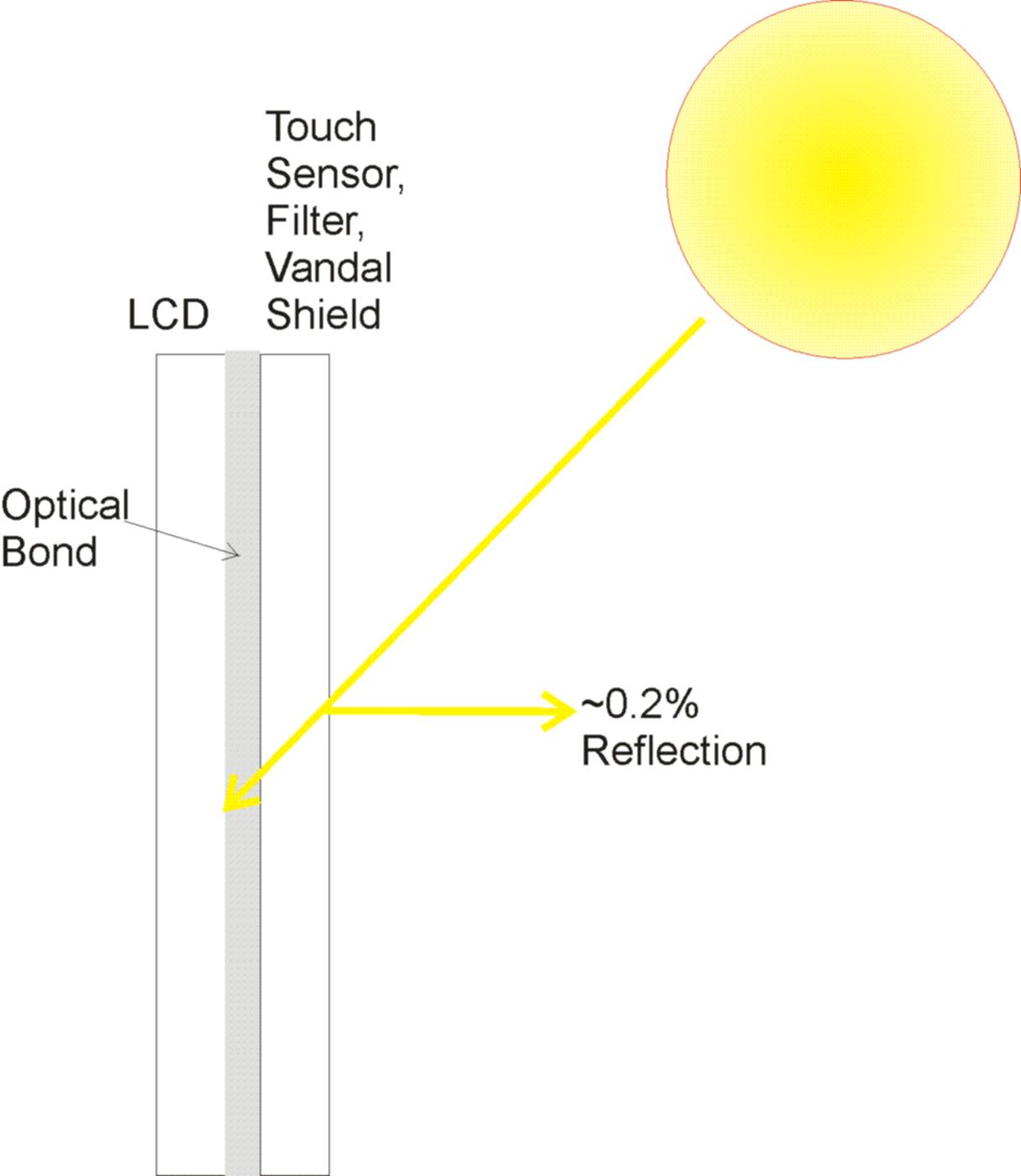

By applying and curing an optically clear bonding liquid between a

substrate material such as a touch sensor, anti-reflective or anti-glare

glass, vandal proof glass or any combination of these and an LCD, we create a solution that adds levels of ruggedization and reduces layers of reflection which is one of the root causes of sunlight or high ambient light wash out of an image on an LCD.

Optical Bonding removes two internal reflective surfaces by eliminating the air gaps between the LCD surface and the rear side of the outer glass or plastic substrate. AR (Anti-Reflective) material or coatings on the front surface increase the contrast ratio even further. A 20% improvement in contrast ratio is typical with this treatment which is a key element for viewing images on an LCD under high ambient or direct sunlight circumstances.

When combined with Display Logic’s high performance, low power LED backlight enhancements, the Optical Bonding process enables the best in outdoor LCD viewability.

Typical Perimeter Tape Attach Method

Click below to speak to a Display Logic representative to learn more