Resistive Technology

Resistive touch panels are one of the most adopted technologies. There are several types of resistive touch panels based on different detection principles, among which the 5-Wire is the best option in durability and reliability. The most noticeable advantage of the 5-Wire is that both the X and Y axes are detected on the lower layer, while the upper layer is used as loop conduction. Therefore, it allows for stability, sensitivity and accuracy even in a severe environments.

4-Wire Resistive is the simplest of touch technologies and the most competitively priced. It uses both the upper and lower layer of the sensor to determine the X and Y coordinates. Advantages include low cost, easy adoption and customization. A drawback of this technology is that the constant flexing of the upper active layer can shorten the life of the sensor accuracy. Cutting the top layer renders the sensor non-functional and overall visual performance can be poor depending on the manufacturer.

However, both technologies are well-tested in many markets and

Display Logic offers well-supported solutions for each:

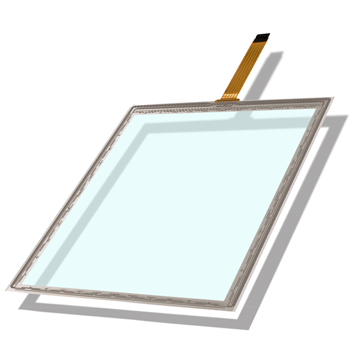

For more severe applications where the normally plastic front layer of a resistive touch sensor would be subject to abrasion or cutting, Display Logic offers 5 wire touch sensors with a laminated layer of micro thin glass. The result is a scratch resistent, waterproof resistive sensor ideal for most military, industrial and public access applications.